Understanding the Characteristics of Flow Control Valves

Choosing the right flow characteristics is necessary to have the correct flow control valve. Basically, it’s a relationship between the opening and the flow capacity of the valve. A proportional solenoid valve has two flow characteristics, Inerent Characteristics and Installed Characteristic.

Whenever a flow control valve works with a constant pressure drop without including the effect of the piping system then it’s known as the inherent characteristic. But when the proportional valve operates with varying pressure drop and considers the effect of the pipeline then it is known as the installed flow characteristic.

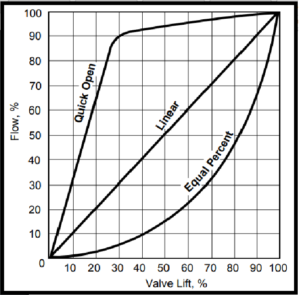

Below we have listed three flow characteristics of the proportional flow control valves:

Linear Flow Characteristic:

This type of characteristic defines that the flow rate of the passing fluid is directly proportional to the flow path. Proportional solenoid valves that have linear characteristics are good for controlling the flow rate of the liquids. The linear flow characteristic is good for the system where the pressure drop is taken from the valve. This type of flow characteristic delivers an improved flow capacity throughout the entire stroke. The piping effect can alter the flow characteristic from linear to inherent quick flow characteristic.

Keep in mind if the upstream pressure is constant and the pressure drop is taken through the proportional solenoid valve then you should choose the linear characteristics because it will provide a strong control. This type of flow characteristic is also recommended for the systems that have a flowmeter.

Quick Open Flow Characteristic:

Having a quick flow characteristic means that the majority of the flow will pass at the first opening of the valve. The curve of this characteristic is linear for the first 40 % of travel and after that, it is flat as you can see in the above-listed pic which shows a small increase in the flow rate of the fluid when it reaches the open state of control valve with solenoid.

Equal Percentage Flow Characteristic:

All the proportional solenoid valves that have equal percentage flow characteristic enhances the flow rate at each lift of the valve. In this type of flow characteristic, the flow rate is small and reaches a high magnitude at the end of the stroke. It delivers accurate control to the user during the first half of the stroke. At this point, it’s not easy to maintain strong control because here the force of the process can affect the control of the controlling element. In the other half of the stroke, this flow characteristic provides high flow capacity at the second half stroke. Thus, this flow characteristic provides better repeatability and improves the rangeability.

Remember that if the equipment or the piping creates a resistance then you should choose the equal percentage characteristic. Today, this is one of the most usual cases of many processes. This characteristic is good for applications in which you have to face low-pressure drops with a high flow rate and a high-pressure drop with a low flow.

Final Words:

Numerous types of proportional solenoid valves are available which makes the selection process difficult. To choose the right fit and to get the precise output as per your need it’s vital to choose the right characteristics.